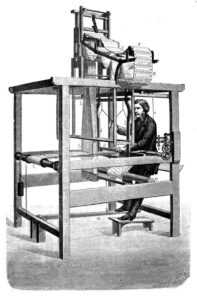

Weaving fibers to form a fabric has been a part of human existence since ancient times. Weaving is the process of interlacing longitudinally oriented warp threads with horizontally oriented weft threads to form a woven fabric. Weaving is performed on a loom, a device arranged to hold warp threads under tension while allowing the weft threads to be sequentially added to them, to produce a fabric. The relative movement and positioning of the warp and weft threads during the weaving process results in a sequence of thread placements that together form a pattern in the finished fabric. To change patterns, the sequence of thread placements must be modified, a traditionally labor and time intensive process. Through the centuries, looms have had a variety of configurations, but their basic function has remained the same.

placements that together form a pattern in the finished fabric. To change patterns, the sequence of thread placements must be modified, a traditionally labor and time intensive process. Through the centuries, looms have had a variety of configurations, but their basic function has remained the same.

Loom technology has seen a variety of innovations throughout history in a continuous effort to make fabric production faster, easier, and more cost-effective. The Jacquard machine invented by French weaver Joseph-Marie Jacquard (born 1752 in Lyon, France) revolutionized the field of weaving. His invention, which uses punch cards to represent a desired sequence of thread placements during operation of the loom, greatly reduced the labor involved in the process of weaving. Jacquard designed a device that would be attached to a loom to control the placement of individual warp threads according to a pre-set progression of steps represented and controlled by a pattern of holes in each of a set of punch cards. This allowed looms to not only produce complex textile patterns such as brocade, damask, and lace, but also to be changed quickly from one pattern to another. By simply exchanging a first set of punch cards for a second set of punch cards, the loom could be reprogrammed to produce a new fabric pattern. Jacquard looms are used for weaving all sorts of intricate patterned textiles. They could be programmed to weave a single pattern fabric or a combination of patterns with different colors. Continue reading “Programming Fashion”

Color My World: Aniline Dyes in Fashion

The past centuries have seen a variety of cultural and technological shifts, and the fashion world has followed suit. These changes have also had a profound impact on the way we dress. In the 19th century, the commercialization of newly discovered aniline dyes for printed fabrics had a profound impact on fashion. The use of these synthetic dyes changed the way we colored fabrics, allowing manufacturers to scale up production. Aniline dyes made it easy for manufacturers to print on a wide range of fabric types all with consistent hue and tone of the color between batches. This allowed for the reemergence of the dyeing industry, which was formerly languishing because of its long dependency on expensive naturally derived pigments. Continue reading “Color My World: Aniline Dyes in Fashion”

From Coal Tar to Couture: The Discovery of Aniline Dyes and The Effect Upon Fashion

Around 1856 an 18-year-old British chemist named William Henry Perkin changed the world of fashion forever. He had been performing experiments seeking to replace the natural anti-malarial drug quinine. Instead of the colorless powder he had expected, he found that oxidizing aniline, a coal tar derivative, produced a reddish powder containing something far more exciting: an intense purple. Fashion would never be the same! This discovery led to the wide commercial availability of low cost, brightly colored fabrics that would be available to all. It also marked the beginning of a hugely profitable business. Continue reading “From Coal Tar to Couture: The Discovery of Aniline Dyes and The Effect Upon Fashion”